Combined cooling, heating and power (CCHP) systems can significantly improve the energy efficiency of a supermarket, according to Ady Vyas, Vice President of Sales and Operations at Neelands Group, a Canadian HVAC&R contractor.

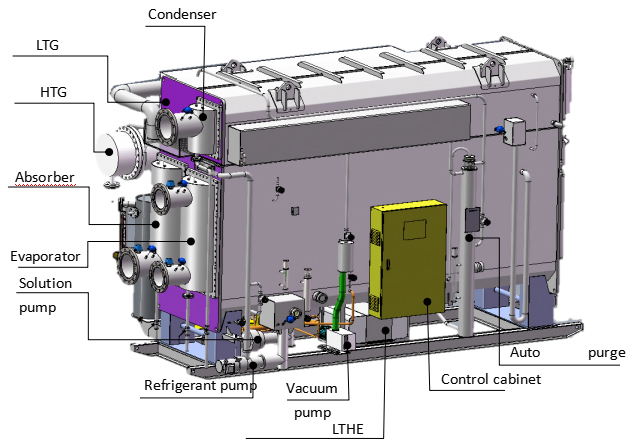

A CCHP system uses microturbines to produce electricity for a store, and the units’ waste heat can then be used for space heating and hot water production when paired with a heat recovery system and for space cooling and refrigeration when combined with an absorption chiller, he explained. Hot Water Absorption Chiller

“With [CCHP] systems running at 85% efficiency, [they] provide energy savings and resiliency,” he added.

Vyas delivered these remarks during his presentation for the Contractors Panel at the ATMOsphere (ATMO) America Summit 2023 on natural refrigerants. The conference took place June 12–13 in Washington, D.C., and was organized by ATMOsphere, publisher of R744.com.

Ontario-based supermarket chain Longo’s partnered with Neelands to retrofit one of its 40 stores. During the refurbishment, the retailer opted to replace its existing refrigeration system, which used a synthetic refrigerant, with a CCHP system.

The system comprises two Evapco LMP CO2 (R744) racks, two Capstone C65 microturbines with integrated hot water heat recovery and an 81TR (284kW) direct exhaust absorption chiller, which uses a lithium bromide solution as a refrigerant.

During the summer, while some of the recovered heat is used for dehumidification, the majority powers the system’s absorption chiller to subcool the store’s refrigeration system.

“The absorption chiller provides chilled water to the CO2 racks, subcooling the refrigerant, and thereby improving the system efficiency,” he added.

When the absorption chiller is running, it reduces the load on the refrigeration system’s compressors, which results in a 20–25% performance improvement and translates to energy savings, he said.

“The absorption chiller provides chilled water to the CO2 racks, subcooling the refrigerant, and thereby improving the system efficiency.”

In winter months, when the store’s heating demand is high, waste heat from the electricity turbines is piped directly into the building, providing free heat and offsetting the need for a fossil fuel-based heating system, he explained.

The system has been operational for just over a year and is performing “as expected,” said Vyas.

When operating, Longo’s microturbines produce more than one million kWh of electricity, which covers roughly half of a typical grocery store’s energy consumption, explained Vyas during his presentation.

“The integration of the absorption chiller offsets another 250,000kWh a year because of the way it interacts with the refrigeration system,” he added. “Hot water heat recovery is also expected to offset more than one million kWh a year of gas-fired heating.”

The realized energy savings will result in reduced operational costs, which will lessen the perceived “cost burden” of CO2-based refrigeration systems, he said.

It is expected that the supermarket will see a return on its investment within roughly six months.

“The integration of the absorption chiller offsets another 250,000kWh a year, because of the way it interacts with the refrigeration system.”

Additional savings can be gained through income tax credits available under the U.S. Inflation Reduction Act (IRA), which can cover up to 40% of CCHP system costs, he noted.

In addition to operational savings, Vyas said the lifespan of equipment is expected to be improved, thanks to the CCHP system. For example, reduced load on the refrigeration system’s compressors should result in extended use.

When combined with CO2-based refrigeration, this project will reduce the store’s greenhouse gas emissions by 1,400 metric tons per year. According to Vyas, microturbines have the lowest emissions of any combustion technology.

The system was also easy to install, with zero shut-down time due to contractors working out-of-hours.

Neelands has been working with Longo’s for more than 30 years and supporting the retailer with its CO2 refrigeration for more than a decade, he explained. According to a presentation at ATMO America 2022, all new Longo’s stores will use R744-based refrigeration technology.

Absorption Refrigeration Username or email address *